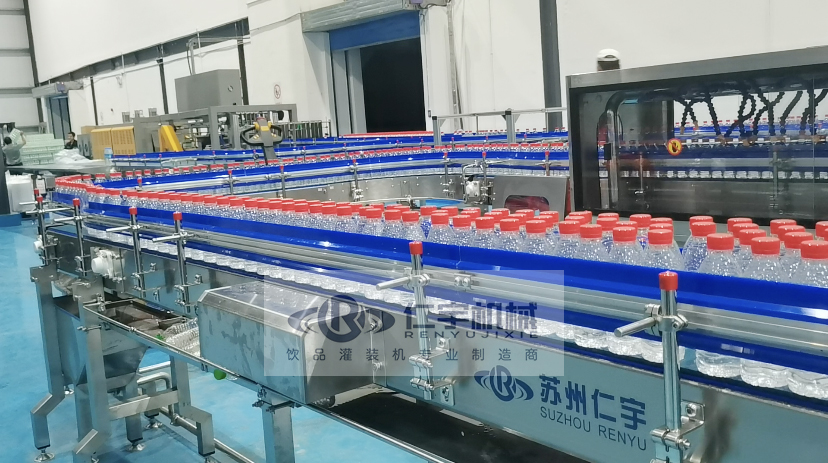

XGF series water filling machine produced by Renyu Machinery integrates washing, filling and capping functions. It is designed according to the requirements for filling and processing of mineral water, purified water and other non aerated beverages by drawing on advanced foreign technologies.

Workflow:

Bottles are fed into the three in one washing machine through the star wheel from the blower. The bottle clamp installed on the rotary wheel of the bottle washing machine clamps the bottle mouth and makes a 180 degree turn along the guide rail to make the bottle mouth face down.

At the designated section of the rinsing machine, water will be sprayed from the special nozzle to wash the bottles on the inner wall. After washing and dripping, the bottle clamped by the bottle clamp shall be rotated 180 degrees along the guide rail to restore the bottle mouth upward.

The cleaned bottle is removed from the rinsing machine through the star wheel. After entering the filling area, the bottle is fixed by the supporting plate supported by the neck, and the supporting plate is driven by the bottle supporting mechanism to lift the bottle to connect with the filling valve.

Filling is done by gravity. The material is filled into the bottle through the filling valve. The bottle drops and leaves the valve to the capping machine through the neck handling star wheel.

The anti rotation blade on the closure head will grasp the neck of the bottle to prevent it from rotating and keep it upright. The capping head makes revolution and rotation with the machine, and completes the whole capping process of capping removal, capping release, capping screwing and capping off under the control of the cam.

Main features:

1. This machine has compact structure, perfect control system, convenient operation and high degree of automation.

2. The arch plate can change the filling bottle shape simply by replacing the star wheel.

3. The part in contact with the product is made of high-quality SUS, which is corrosion resistant and easy to clean.

4. Fast flow rate, high filling accuracy, accurate liquid level, no liquid loss, meeting the requirements of filling process.

5. The sealing head adopts a constant torque magnetic device to ensure the sealing quality and impact sealing.

6. This machine has an efficient lid management system, perfect automatic control and self-protection device for lid.

7. The machine adopts perfect overload protection device to ensure the safety of the operator and the machine.

8. The control system has many functions, such as production speed control, cap missing detection, automatic stop for bottle plugging, output counting, etc.

9. The main electric and pneumatic components are world famous products.

10. All controls are operated by advanced touch screen to realize man-machine conversation.

Product model | rinse | filling | seal | Rated output (500ml) | power | Equipment dimensions |

CGF8-8-3 | 8 | 8 | 3 | 2000-3000BPH | 2.2 | 1900*1450*2100mm |

CGF14-12-5 | 14 | 12 | 5 | 4000-5000BPH | 2.2 | 2600*2100*2200mm |

CGF18-18-6 | 18 | 18 | 6 | 6000-8000BPH | 3 | 2700*1900*2300mm |

CGF24-24-8 | 24 | 24 | 8 | 11000-13000BPH | 4 | 2940*2300*2300mm |

CGF32-32-10 | 32 | 32 | 10 | 15000-18000BPH | 5.5 | 3750*2900*2300mm |

CGF40-40-12 | 40 | 40 | 12 | 22000-24000BPH | 5.87 | 4450*3100*2300mm |

CGF50-50-15 | 50 | 50 | 15 | 28000-30000BPH | 7.87 | 5450*3300*2500mm |

CGF60-60-18 | 60 | 60 | 18 | 35000-36000BPH | 7.87 | 6500*4500*2900mm |